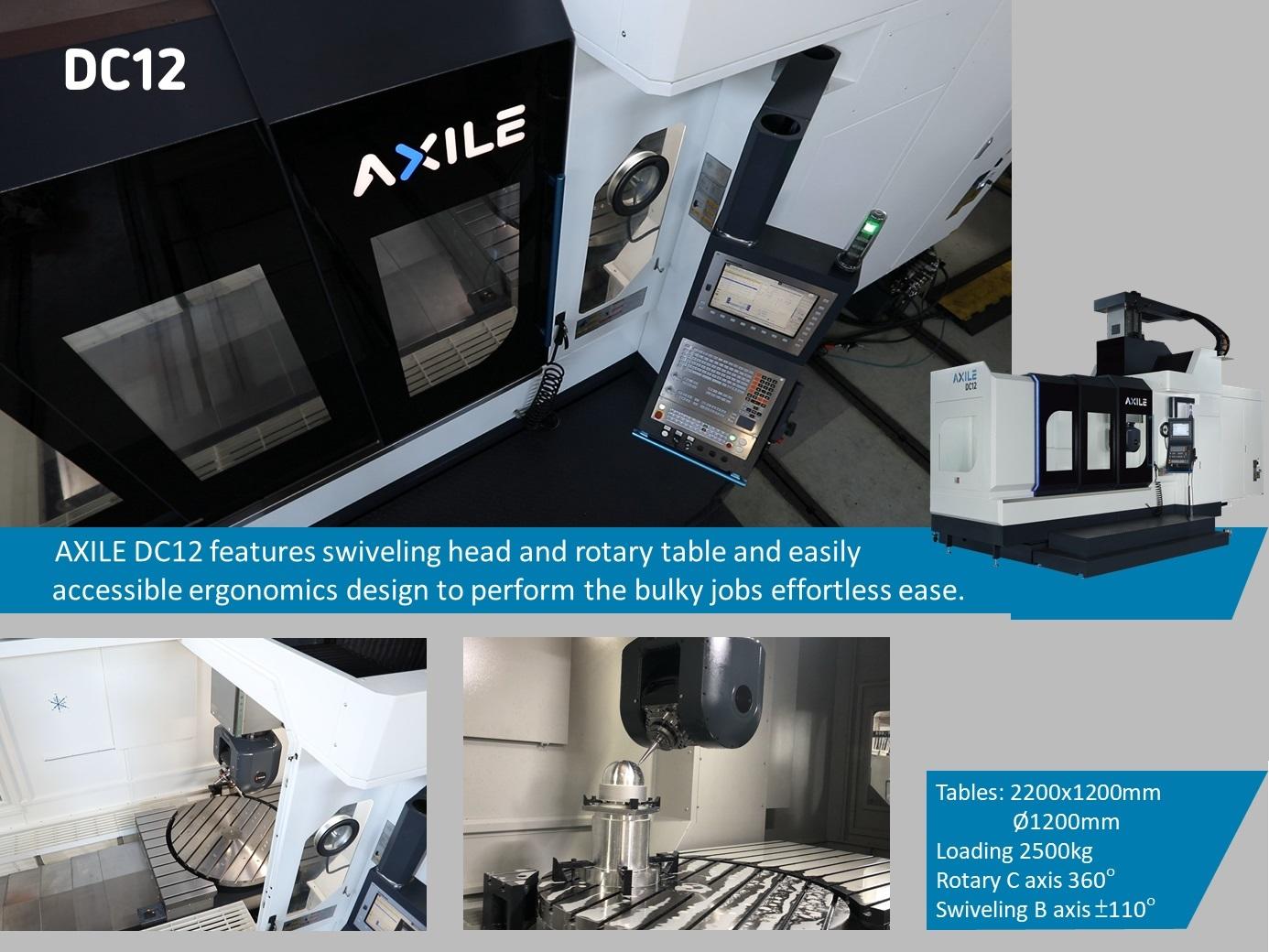

Buffalo Machinery aims to continually enhance the performance and functionality of product. The new DC12 handles 5-axis simultaneous machining for complex parts, and the equipped extensive working table allows to process larger workplace in 3-axis milling, high flexibility well suits for the efficient machining in Aerospace, Die&Mold and Medical industries.

Highlights:

| |

▪ |

High performance built-in spindle of HSK-A63, 20000rpm(std) or HSK-A100, 16000rpm(opt) for the utmost machining quality. |

| |

▪ |

Dual table design of 2200 x1200mm and rotary C axis of Ø1200 mm with loading capacity up to 2500kg. |

| |

▪ |

Large capacity tool magazine with full guard for 5-axis simultaneous machining and increase higher accessibility and safety for maintenance work of the ATC. |

| |

▪ |

Smart Tool-Load Station with control panel are equipped at side of the magazine for easy tool loading/unloading. |

| |

▪ |

The composed of swiveling head with ±110 degrees and 360-degree rotary table. |

| |

▪ |

Integrated absolute encoders enable swiveling-rotary axes the tracking accuracy of ± 5”. |

| |

▪ |

Extra-wide door-open width of 2200mm, which perfectly fits the X axis travel for easy loading of workpiece. |

RELATED CONTENT

AXILE Double Column Type 5-Axis Machining Center