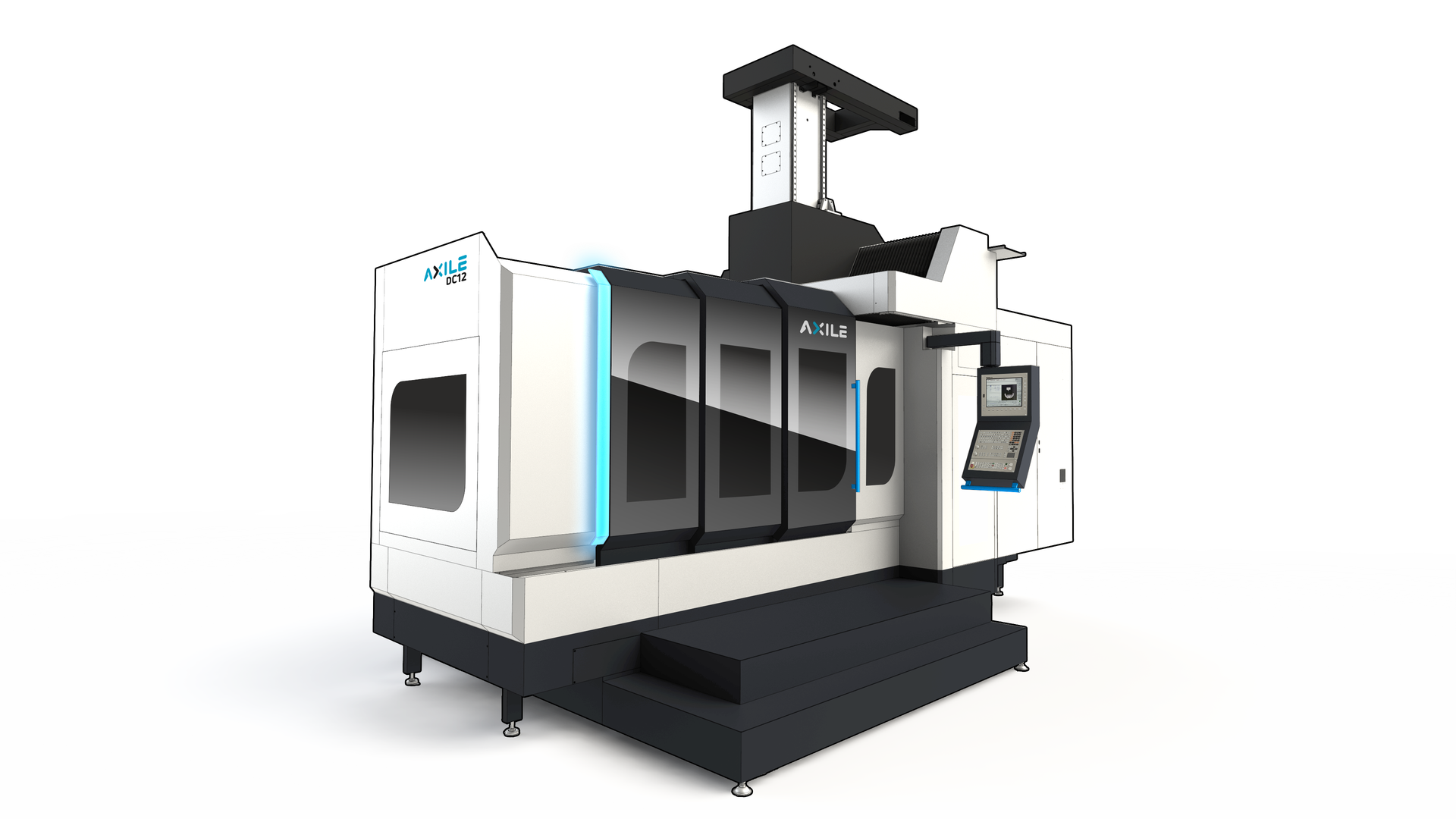

AXILE will present its advanced machines at EMO Hannover (16-21 September 2019, Hall 27/ B63). To meet various industrial demand, Buffalo Machinery has developed machines and expanded its product portfolio continually. One highlight will be the double column type 5-axis machining center, DC12, the high-speed machining solution for heavy-duty cutting.

With built-in spindle of 20,000 rpm of HSK-A63 spindle taper with 90 tools (STD) and 120 tools (OPT), DC12 offers high-speed machining capacity. Moreover, DC12 also provides 16,000rpm spindle option of HSK-A100 spindle taper with 60 tools for users who are looking for high-torque to do hard material cutting.

DC12 is developed as bridge-type construction, it combines heavy cutting and high-speed 5-axis machining capabilities in one machine. DC12 provides an ultra-large work area with 2200mm x 1200mm table with 2.5 tones loading capacity and 1200mm diameter rotary table for more dynamic machining, the table is supported by one-piece casting base which can handle heavy and large workpiece. For the z-axis headstock, it is mounted on a 4-guide ram and equipped with advanced automatic compensation balancing system (SCBS) to ensure the rigidity in any machining direction using the box in box concept. Additionally, 3 linear guideways for Y-axis to ensure rigidity while heavy-duty cutting and allows the ram to move smoothly and steadily guided all the time.

DC12 is a profitable performer who is excellent for precision machining for extra heavy parts with complex contouring ability. Please come and visit AXILE at EMO Hannover Hall27, B63 to experience this notable machine.