SERVICE INQUIRY (*Required)

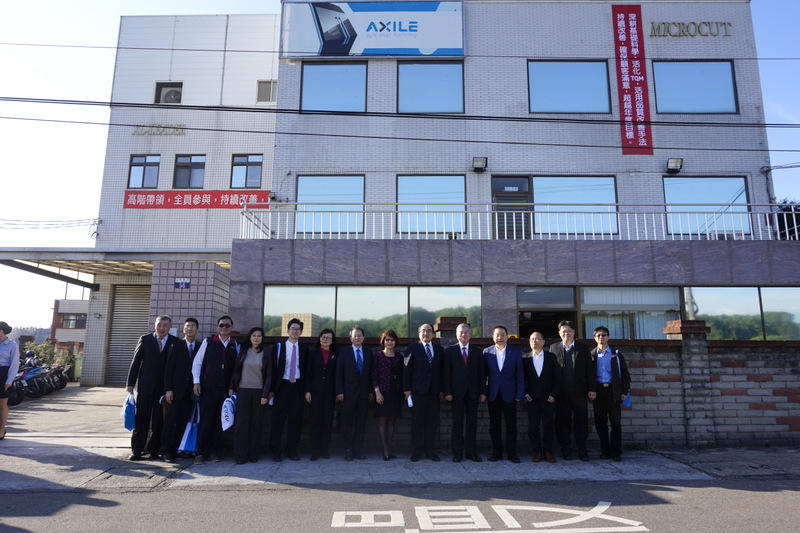

To promote domestic development of Industry 4.0 in Taiwan, in December 2019, the delegation of the Economic Affairs visited Buffalo Machinery to learn how Buffalo Machinery achieves the Industry 4.0 Intelligent production flow, machine reliability enhancement and the operating results of quality control. In addition, held a short conference aiming at discussing the future of Taiwan Smart Manufacturing and Industry 4.0 technology development.。

|

|

Dr. Chang introduced Smart Production lines to Minister Shen |

It's Buffalo’s great honor to have an opportunity for this interview. Buffalo introduced and presented the Smart Production lines to the delegation, meanwhile explained the key to build the traditional manufacturing site to meet the requirements of the Smart Manufacturing, and how it was performed and transferred from traditional production management. By implementing the self-designed big data analytics solution, Timesheet Electronic System, which integrating Buffalo's manufacturing data and the market sales prediction, the data from various factory sites can be collected, and abnormal situations of production scheduling occurring can be immediately noticed and resolved, to intelligently manage the production line, improving management efficiency in manpower, production progress, material resources, which helps Buffalo maintain a competitive advantage in operational management control and production efficiency improvement and yield rates.

Buffalo Machinery has been contributed to the innovative development and production for decades, involving internally strengthening on the practice of TQM with massive effort, and focusing toward the right path to mechanical automation as a whole, eventually established the largest five-axis machine manufacturing base in Asia. AXILE has successfully entered several markets, such as European and American aerospace industries and automotive mold industries due to high-tech quality insurance. Besides, Buffalo now ranks in the fourth machine tool manufacturer out of five-axis machine market in Europe. Facing the global smart manufacturing trend, Buffalo was benefited from its foreseen and early efforts on fusing advanced mechanical design and electrical techniques to build high-precision five-axis machining center, and soon embarked on the develop Industry 4.0 ARTTM system.

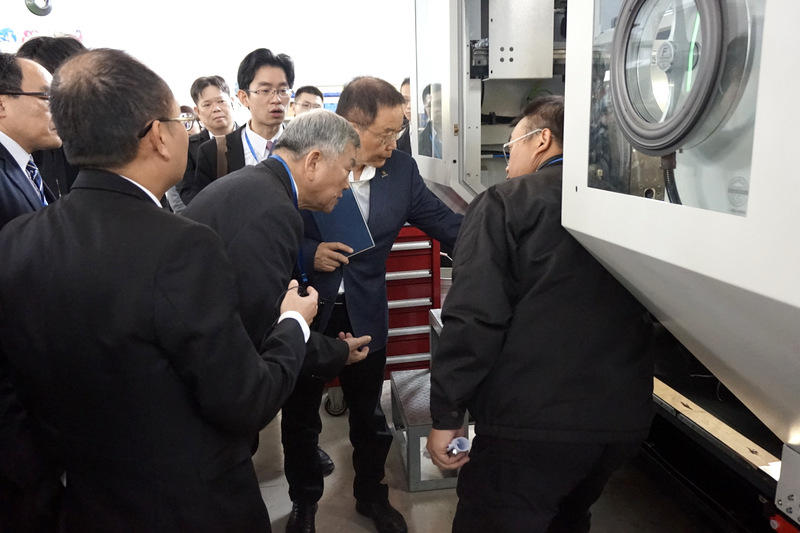

The delegation was particularly interested in the technical details of the five-axis machine and its applicability who paid particular attention to the application of all key components. Having taken a look at the brief instruction of AXILE five-axis machine and ARTTM Industry 4.0 software, and the actual machine demonstration, the head of the delegation, Minister Shen, affirmed that the AXILE machine achieves continuous unmanned 24/7 production , and he also gave recognition to the remarkable achievement of mechanical reliability.

|

|

|

|

Delegation of Taiwan Economic Affairs visiting the 5-axis machine manufacturing |

||

The five-axis machine, with the integration of Industry 4.0 ARTTM system, can get connected to the ERP system at the production site. The customer and supplier are more closely linked in innovative ways, enabling the machine to perform 24/7 automation without unexpected downtime. Nevertheless, it features the ability to sense in advance and predict occurred issues, so that the equipment itself can respond promptly according to actual changes in the manufacturing process, which meets the production requirements of Smart Factory. AXILE 5-axis series offers the possibility of fully integrating high accuracy machining, sensor application and surveillance, predictable technology, and IoT in one to reach unmanned automation.

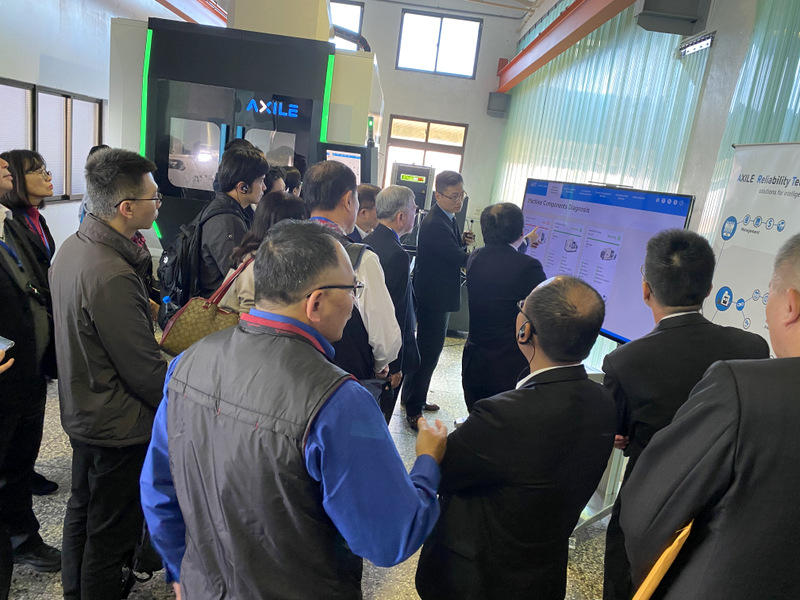

Buffalo Machinery arranged the demonstration at the Application Center to further explain ARTTM system. The demonstration showed competitive advantage of ARTTM system, including real-time monitoring machine status through IoT, supplementary notification of consumables, power consumption and production scheduling adjustment. Through data analysis, users can be informed by the system to grab the predicted maintenance needs of the machine in advance, and therefore to plan the schedule early without stopping production due to failure and downtime, which significantly affects production line capacity.

|

|

|

|

The demonstration of Industry 4.0 ARTTM system at Buffalo’s Application Center |

||

At the end of visit, Minister Shen encouraged that Ministry of Economic Affairs will be able to effectively assist the development of key components and system components of the domestic industrial industry in the future, mainly set a consensus on the development in the domestic industry, and group them into a common standard for Taiwan’s manufacturers, so as to enlarge the international markets. Furthermore, to encourage individual companies with innovative plans and strategies to develop their unique technologies, to further promote industrial upgrading and optimization at the following stage. Some individual companies in Taiwan have been breakthroughs in this area and we hope to continue to make contributions in areas that are of particular concern to the whole industry.