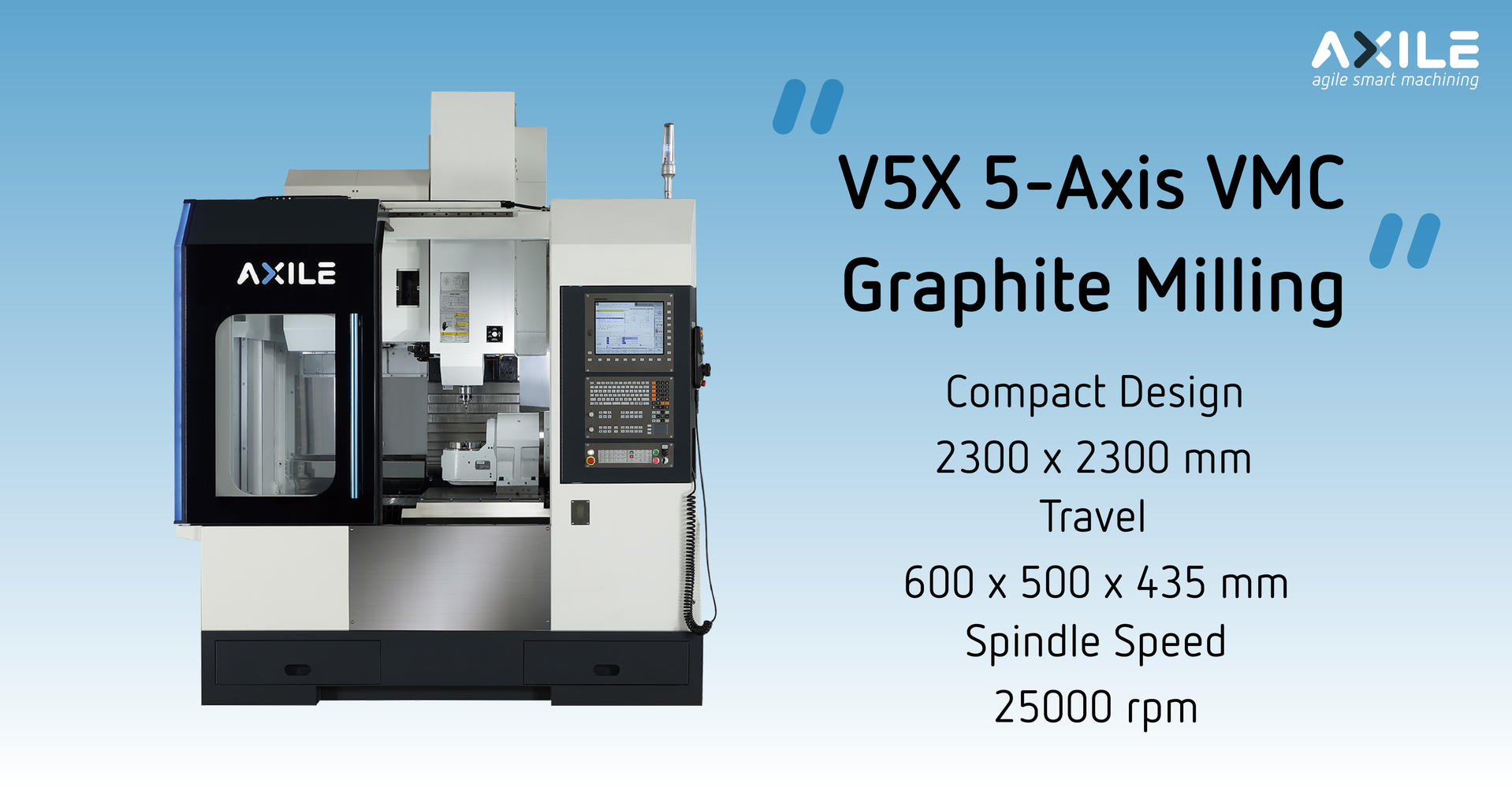

AXILE V5X has a compact footprint of 2300x2300mm with 600x500x435mm travel, its compact design is the great choice for job shop owner whose floor space is at a premium. And the workpiece size is Ø210x350mm, which is suitable for machining small and complicated parts. The C-type structure ensures V5X performs high rigidity of Z-axis and spindle headstock. And the built-in 25,000 rpm spindle is good for high-speed graphite milling.

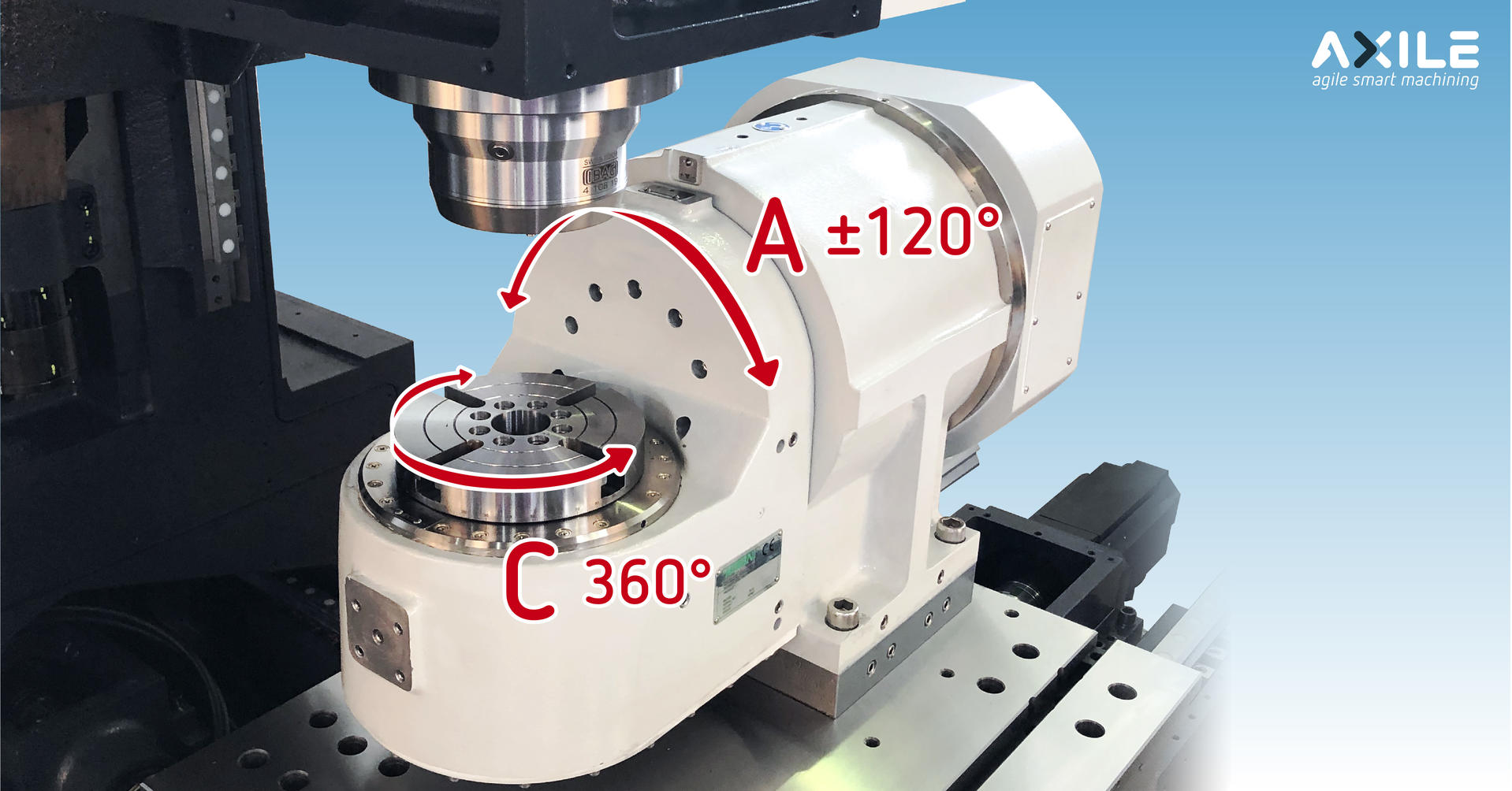

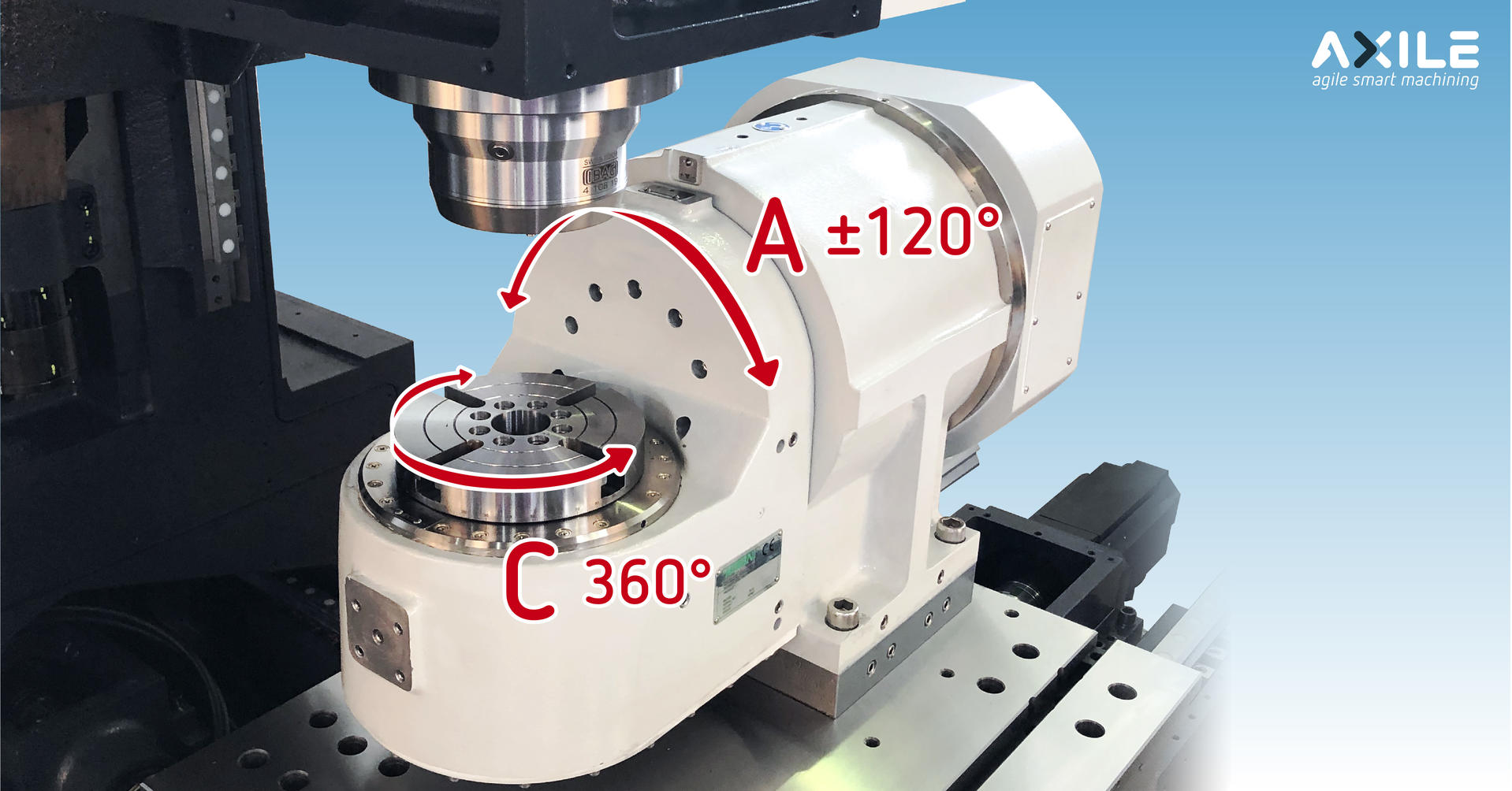

V5X offers 5-axis simultaneous machining capability. With the swivelling-rotary table, V5X helps users minimize many setups to produce complex parts. The titling (±120°) and rotary axis (360°) are driven by torque motor to provide the highest dynamics and accuracy. V5X shows high-precision on contour machining.

To keep cleanliness in the working area, the dust collector is located at the top of the spindle to optimize the suction. The maximum airflow capacity is 4000m³/h, and the dust collector capacity is 205 L. Also, considering the wearing issue, ballscrew and guideways are below the telescopic cover to avoid the wear and tear.

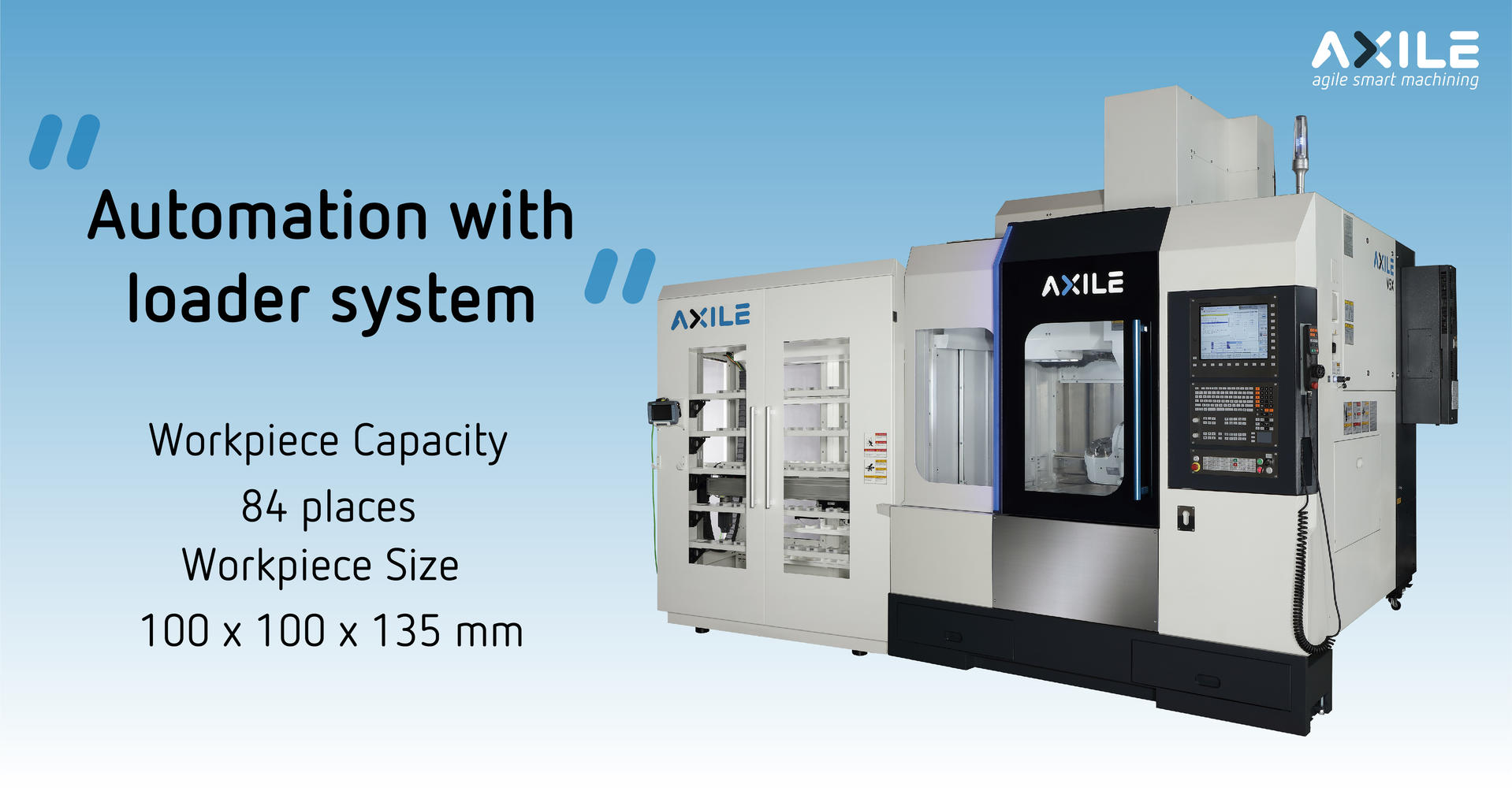

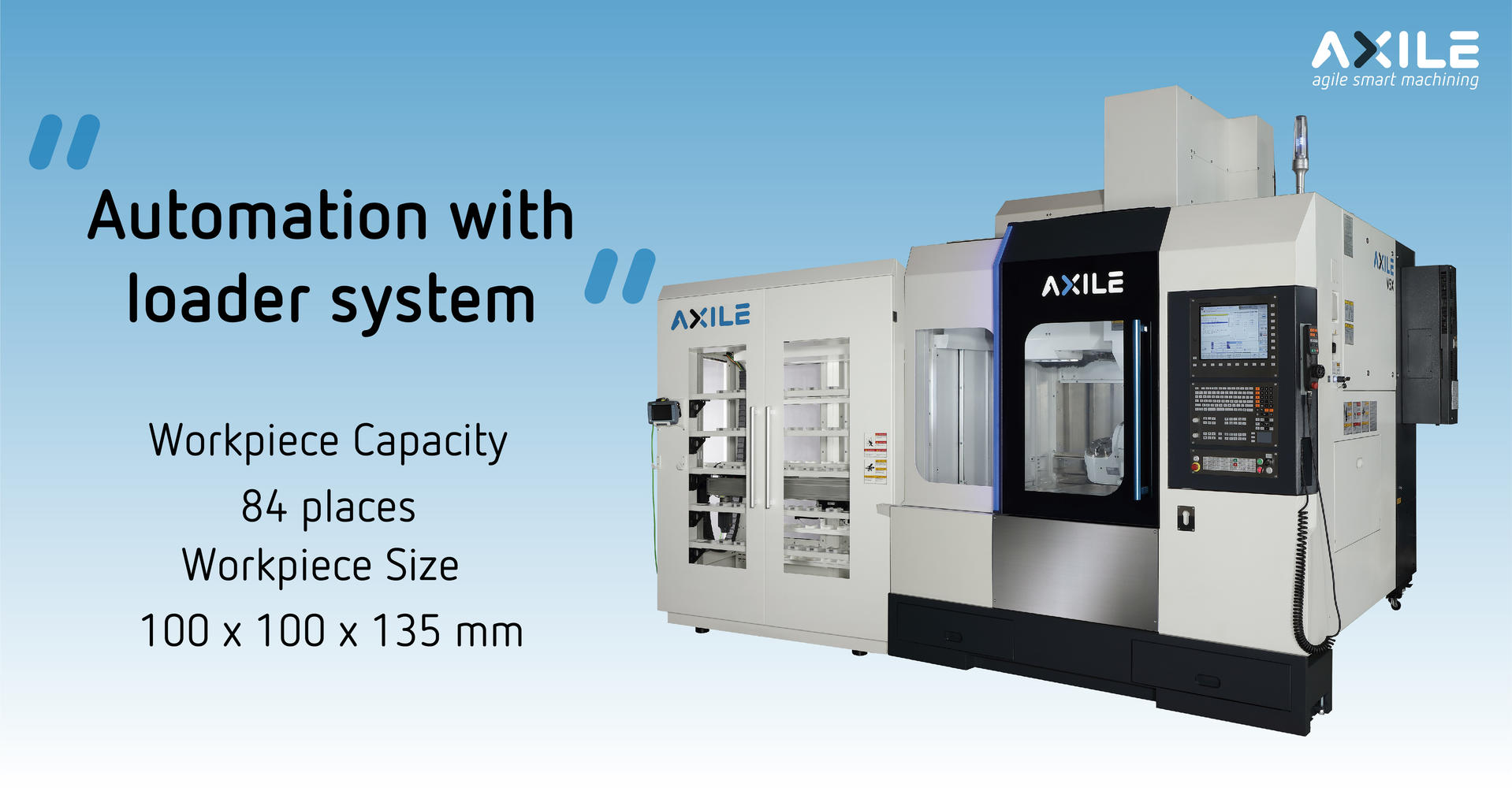

Working with self-developed loader system, V5X provides max. workpiece capacity of 84 places for 100x100x100 mm workpiece size, and max. 8kg workpiece loading.

The V5X is built with AXILE’s Smart Machining Technology, giving the ability to improve machining accuracy and reduce spindle vibration during the machining process. Also, users can freely select the control system based on their preference, from HEIDENHAIN TNC 640, SIEMENS 840D sl to FANUC 31i-B5 Plus iHMI Pro.